Applications

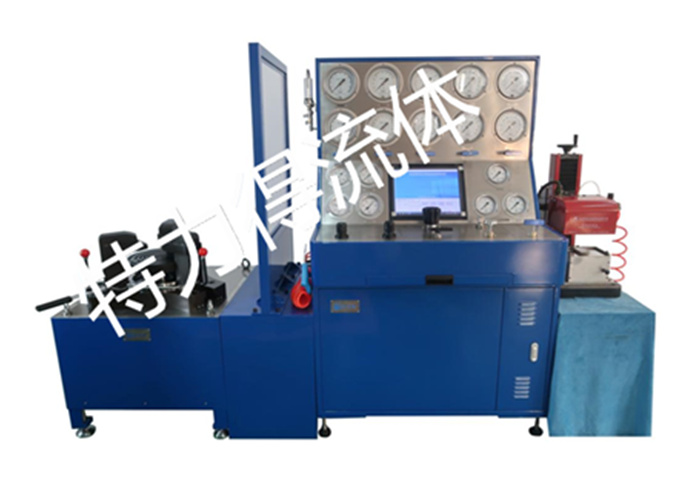

High, medium, and low pressure gas test bench (Integrated recorder) TPU-3100-3R

Suitable for set pressure test and seat tightness test for all types of SRV, according to common international test standard-API526, API527, ANSI/API RP576.

1. This equipment consists of three main parts: control console, clamping console, and PT shield. It is used for testing the set pressure and seat tightness of safety valves.

2. The overall design of the equipment conforms to ergonomics, including the height of the clamping console, height of the pressure gauge, valve position, display position and angle, etc. The operation panel is arranged and indicated according to the flowchart.

3. The control console panel is installed with a 15 inch LCD touch screen, with a drawer for keyboard and mouse.

4. The equipment is standard equipped with data acquisition system which is independently developed by our company. User friendly, analysis and registration of valve test. Data acquisition software can automatically generate reports. The report content meets national standards and user requirements.

5. Equipped with five sets of precision pressure gauges with different ranges on the panel, convenient for users to compare with two gauges. Equipped with corresponding pressure sensors.

6. The high-pressure booster is the American Sprague product which is our company's agent brand. Fast boosting and good pressure retention, and can be used for a long time without maintenance.

7. Equipped with a high-pressure gas pressure regulator, the output pressure is infinitely adjustable.

8. Hydraulic automatic clamping system is developed independently, with safe and reliable clamping, pre clamping, precise clamping and other clamping methods, making it convenient for a single person to quickly complete testing.

9. Clamping console is with centering three claw linkage, labor-saving and convenient for quick clamping.

10. The clamping console has strong rigidity and reasonable structure, which is convenient for small valves and suitable for large and heavy valves.

11. The product has high efficiency and can be used without faults for a long time. It can quickly recover investment and generate long-term benefits.

1. Test medium: Nitrogen or clean compressed air;

2. Test pressure: Maximum test pressure 680 bar;

3. Test range: Flanged: DN15-250(1 1/2”-10”)

Threaded: DN15-50(1/2”-2”);

4. Clamping force: 25T;

5. Power supply: Drive air source: 7 bar dry and clean compressed air; Power supply: AC220V, 50Hz;

6. Dimensions and weight:

Overall size and weight: 2162*800*1690, 691KG

Control console: 1030*800*1690, 224KG

Clamping console: 732*732*919, 421KG

PT shield: 400*732*1690, 46g